Welcome to TheCHEMICAL CONTAINMENT BLOG

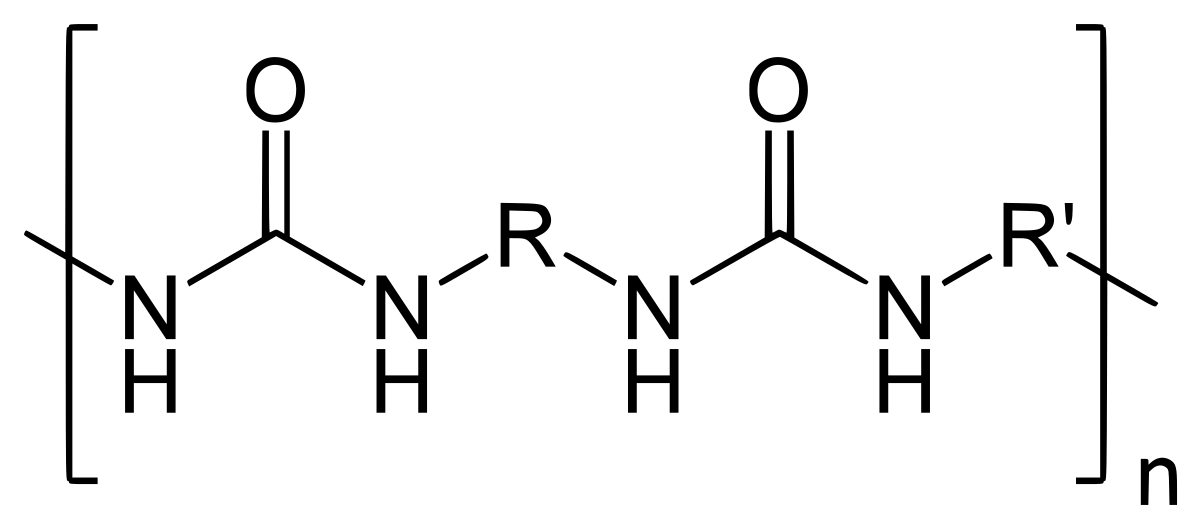

POLYUREA

Polyurea is a type of elastomer that is derived from the reaction product of an isocyanate component and a synthetic resin blend component through step-growth polymerization. The isocyanate can be aromatic or aliphatic in nature.

.

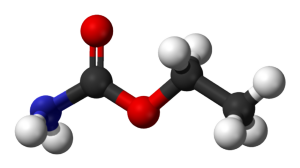

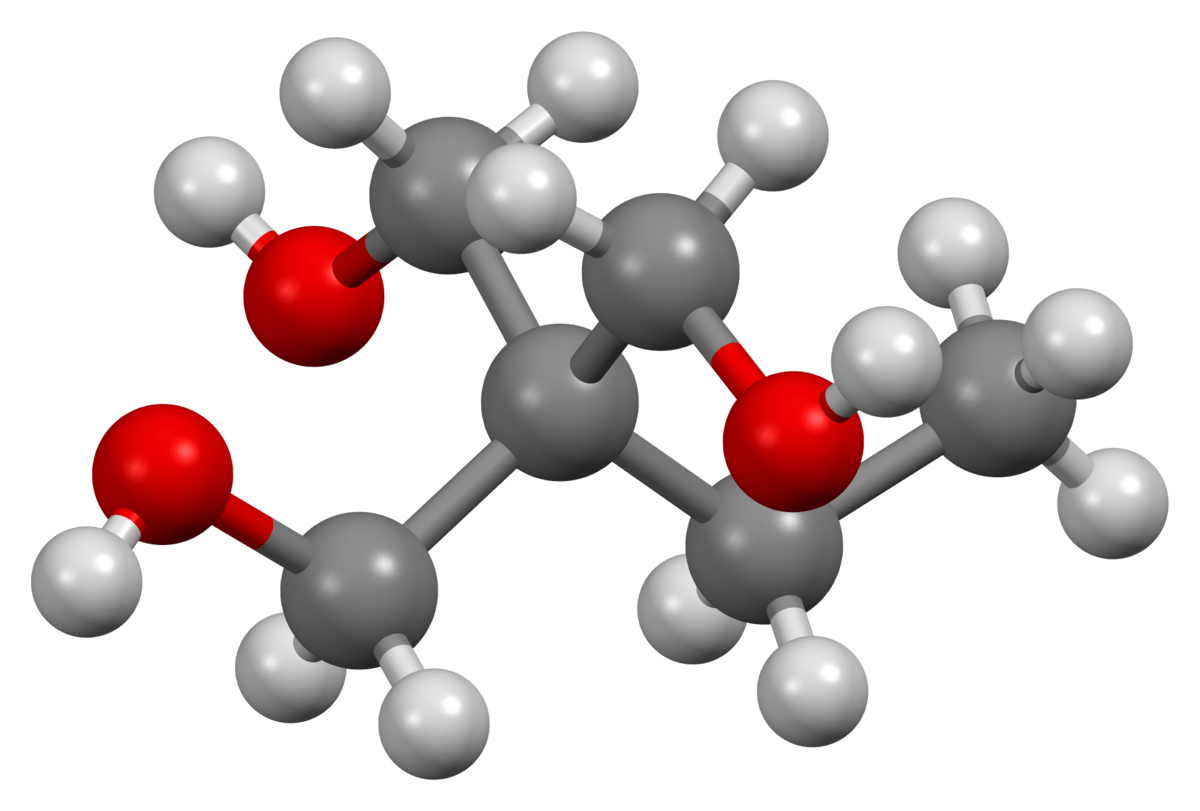

POLYURETHANE

Polyurethane refers to a class of polymers composed of organic units joined by carbamate links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane is produced from a wide range of starting materials.

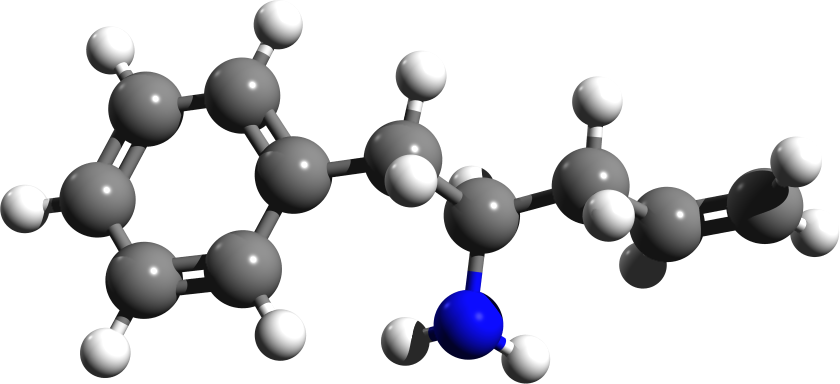

POLYASPARTIC

Polyaspartic ester chemistry was first introduced in the early 1990s making it a relatively new technology. The patents were issued to Bayer in Germany and Miles Corporation in the United States. It utilizes the Michael addition reaction. These products are then used in coatings, adhesives, sealants and elastomers.

CHEMICAL

CONTAINMENT TYPES

Nunc nulla. Vestibulum purus quam, scelerisque ut, mollis sed, nonummy id, metus. Aenean imperdiet. Aenean tellus metus, bibendum sed, posuere ac, mattis non, nunc. Donec interdum, metus et hendrerit aliquet, dolor diam sagittis ligula, eget egestas libero turpis vel mi.

with Best Trainers

OUR TRAINING

Interested In Chemical Containment Training? Call Us Now

CONTAINMENT

CHEMICALS

Polyurea

Polyurethane